Environmental impact

Make it last

Atkins.

Oldest photo lab in Australia, but we still look amazing.

Environmental Impact and Atkins Lab

The short answer:

We do not want to ‘greenwash’ the reader as this is a difficult topic to confront when much of technology we use is half a century old, and a lot of it has been abandoned for faster, shorter lifespan, lower quality, technology. The second issue is quality, for example: clients demand that our prints are of the highest quality and will last a life time, this cannot be achieved with recycled papers.

We’ve struggled, over the past 20 years, to find how we can be more ecologically sustainable. I think our whole society has, and goal posts keep moving. Early 2020 we installed a 39kw Adelaide made Tindo Solar system. This system comes with remote monitoring, and we have followed the game and cut our reliance on the grid by over 80% on average month to month.

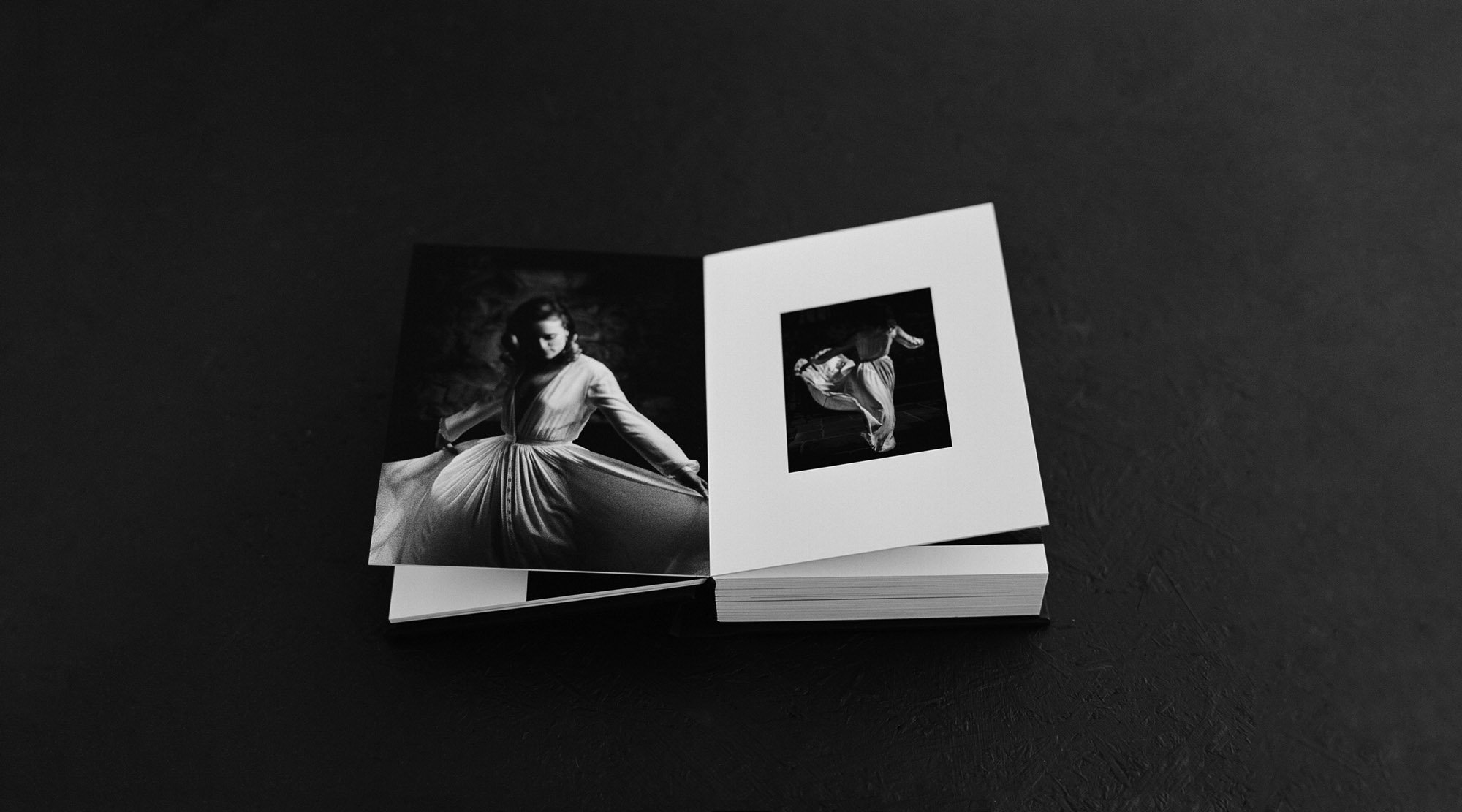

The reality is we reuse everything we can, we try and make everything locally if possible, we minimise the use of single use plastics and papers, we carefully dispose of anything liquid or other substances and we try to have sustainability in our thinking when designing new products. However, part of this is an attitude of ‘do it right the first time and do it so it lasts’. That means we make things that are meant to be kept for a lifetime and will last a life time. That’s a bigger issue than the odd bit of recycled paper here and there. It’s about living the attitude of a desire for meaningful tangible objects that are cherished and not wasted.

The long answer:

Reduce

We push forward our message of ‘For pictures that matter’. We use the best people and equipment to minimise the wastage to print only the most important pictures. The reality is we must use carefully made highest quality materials to produce prints that are not disposable, we want these prints to survive generations. These materials are rarely recycled. Other print suppliers out there that claim to use recycled papers may also be using printers that require many prints to be done before a print of acceptable quality can be achieved, negating any benefit to a recycled paper. We generally print each image only once, twice if there’s an issue, and also exactly to size so there’s no ‘bleed’ trimmed off. The wastage is very low in our printing methods and papers.

Reuse

We are intense reusers. We keep two rooms of older equipment that we use as spares. We can do this because we have chosen to retain older more serviceable machines. We also retain semi retired maintenance specialists, detailed manuals and instruction logs on equipment issues to keep all of this running. We never ignore new technologies, but we are slow to adopt.

We have ventured into the latest toner based printing to potentially replace our wet and ink systems, we ran a digital press for four years. These toner print systems are commonly what our competition chooses to use. Two key factors scared us off these newer technologies. 1. Wastage generated to maintain the quality was horrendous, 300% wastage was not uncommon. This compares to the 5% wastage for our Traditional Silver Halide printing. 2. The equipment life span is typically 5 years…so in 5 years you need to change the equipment, how is that sustainable?

Lastly, much of the wasted paper we generate goes in to our finishing departments for protection and work surfaces, and for note paper. much of our waste water is added to our dilution tanks so our out flows meet regulations, these out flows are checked every 3 months.

Traditional Silver Halide Printing

Our primary digital printer is now over 20 years old and strongly in service. The wet process machine that develops its prints is close to 40 years old, and runs the latest Kodak RA4 Chemistry which is the pinnacle of sustainable print Ag chemistry. Our Traditional Silver Halide print systems run at around 4-5% wastage through careful maintenance and calibration.

Chemistry replenish systems

Our chemical processes use a replenishment system as opposed to a ‘one shot’ system, where the entire tank is changed with each process run. Essentially, when a sensor detects paper in the bath, it adds just the required amount of concentrate (replenisher) to keep it optimal.

Chemistry heating

The baths of chemistry need to be heated, so we use deep tank processes to minimise temperature drift with big water bath heat exchangers to minimise the fall in temperature overnight. This heating is electrically powered using our 39kw Adelaide made Tindo solar system.

Silver recovery

We use an industrial heavy metal recovery device to remove 99% of the silver from our chemical processes. This is electrically powered by our solar system. The outflows of this are further diluted and tested quarterly to meet regulations. All outgoing water has passed through our filtration systems and meets all the relevant standards.

Inkjet printing

We do use the latest pigment and dye based printers, and we do struggle with their seemingly planned obsolescence. Regardless, they provide amazing quality, and if you take the time, as we have, to learn maintenance procedures from willing service technicians, you can extend their serviceable life. Our wide format 11880 Epson is now nearing ten years old and still producing.

Recycled papers

This is a sore point for us as we have yet to find a recycled print paper that will render the majority of photographic images well. We don’t want to greenwash you with rubbish about sustainably sourced papers, we use what is best and what will last the longest. See also the information about reducing wastage which is a big part of our process.

Frames

Timbers used in our framing products are either sourced from Italy or Australia. Our beautiful Tasmanian Oak is obviously local and one of our most popular frame types. Our Western Australian Karri is also locally sourced and the supplier, Artis Pura have the following statement about their practices:

“We source our timbers from certified timber merchants who share our belief the environment is a resource which must be conserved, and only promote trade in timber sourced from legally constituted and sustainably managed plantations and regrowth forests.

Some private logs are harvested under Local Government Acts in compliance with the Forest Practices Code and Regional Forest Agreements. Our timber merchants are independently audited under the Australian Forest Standard Certification Scheme which ensures that we are only working with legally sourced timbers.”

People processes

Seemingly insane, we have been employing people before reaching for a robot. A good example of this is our book binder’s gluing station. We reviewed a new machine that essentially was a small spray booth that uses pressurised plastic based glue, the whole system draws a lot of power and wastes a lot in daily clean up. We chose to retain our paint roller nightly wrapped in aluminium foil that is loaded with hand made paper paste. We have always tried to keep the efficiency of the perfection of the human touch over the clumsy fake efficiency of yet more power sucking machines.

Learning

We are always learning about what is good for the environment and what isn’t. There are so many different opinions. We try to offer alternatives to clients who are sensitive to animal cruelty, but also without making decisions that would then cause other environmental impacts like using more plastics. These solutions are not always perfect. We love to hear where we can do better and any time clients have made suggestions we have taken as much on board as we can. We will continue to learn and change and adapt.